Eyewear is more than just a functional device; it’s an expression of identity, fashion, and style. In an industry where aesthetics and quality are intertwined, the production constraints of traditional materials—like cellulose acetate—present a significant challenge. Acetate is a beloved material for its visual richness and comfort, but it’s difficult to work with: it’s fragile under thermal stress and not very compatible with precision finishes.

The 3dnextech technology suite rewrites these limits. Through “cold” additive solutions, it opens up a new production landscape for an industry that thrives on differentiation, personalization, and speed.

1. 3DFinisher™: High-Level Aesthetics, Industrial Performance

Imagine a pair of acetate glasses with a smooth, glossy, waterproof, and wear-resistant finish, achieved without dimensional changes or the risk of warping. The 3DFinisher™ treatment works on the polymer’s microstructure, eliminating porosity and layer lines through a process of controlled plasticization, without liquid films or direct heat. The result is a mechanically reliable and visually flawless component, ready to go from the runway to the store.

2. Tattoo™: The Revolution of Permanent Coloration

Personalization and branding can no longer accept compromises. With Tattoo™, coloring becomes permanent and molecular. It’s not limited to a surface coating but penetrates the material’s structure, preserving the piece’s strength and flexibility. This opens up new possibilities for limited-edition collections, regional color variations, and exclusive finishes—every pair of glasses can become a unique piece, serialized directly from the design file.

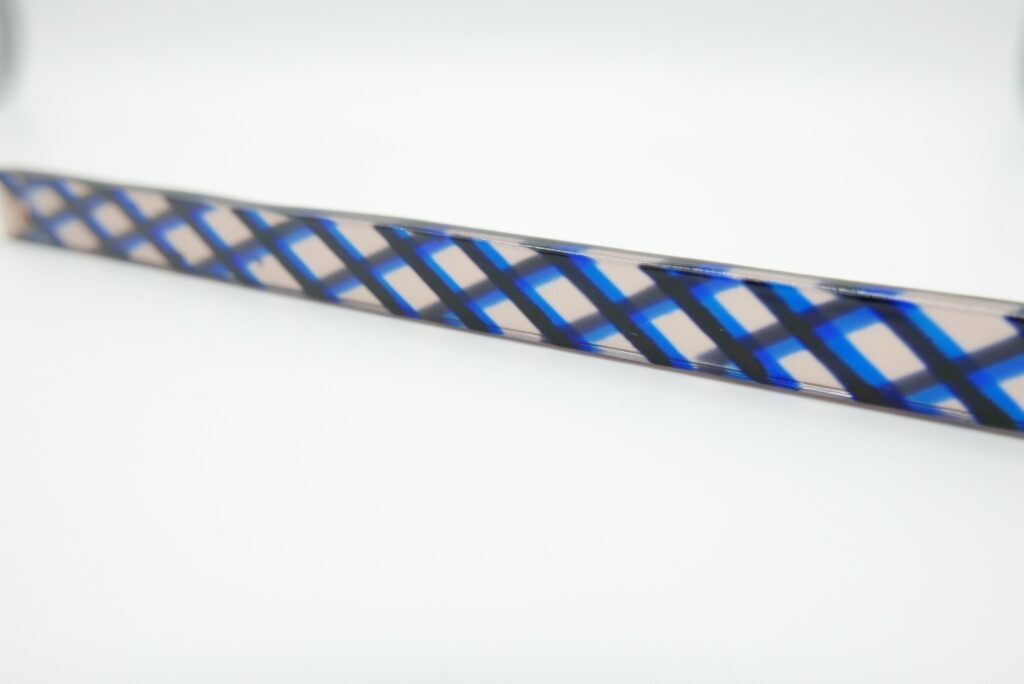

3. Pattern™: Texture, Design, and Functionality

Aesthetics also mean touch, depth, and contrast. The Pattern™ technology allows you to apply complex and repeatable textures to the surface without using molds. Whether you want to simulate natural materials or create iconic patterns, this texturizing process becomes a competitive asset that can be replicated on every series at marginal costs.

4. From Prototyping to Agile Production

Technologies like 3DNprinting and 3DNfilling make it possible to create custom frames or parts on demand, with timelines and costs that are compatible with the fashion cycle. No investment in molds is needed, and there are no minimum quantity restrictions. This means designs can evolve with trends, and pilot series can go into production in days, not months.

5. Production Cells: Flexibility, Localization, Sustainability

The adoption of micro-production ecosystems—the so-called autonomous cells—enables distributed and modular production. A factory in Lucca, one in Tokyo, and one in New York can all be synchronized by a single file and process recipes. The result? Less logistics, less CO₂, and more speed.

Conclusion

The 3dnextech proposal is not just a simple evolution of finishing; it’s a radical transformation of the production process in the eyewear sector. It moves from thermal constraints to geometric freedom, from centralized production to local on-demand manufacturing, and from sacrificed aesthetics to functionality and emotion fused into a single piece.

The next pair of glasses won’t just be beautiful to look at. It will also be smart to produce.