In recent years, the manufacturing sector has witnessed the rapid expansion of additive manufacturing technologies. The speed of prototyping, the ability to customize 3D printed products, and the ease of producing prints with complex geometries that are otherwise unfeasible with traditional technologies are just some of the advantages of using additive manufacturing.

Along with the spread of additive manufacturing technologies, the idea that we are dealing with a fast, simple and automated “pushbutton” technology has also spread.

This statement may be true when referring to the “part-building” phase.

But the additive manufacturing process can’t be reduced to the printing phase alone, and the process that from a file leads to the realization of a finished, ready-to-use product is more articulated than one might think.

In fact, parts resulting from additive manufacturing, regardless of the technology used, require some form of post-production in most cases.

But what does post-processing really mean?

Post-production, or post-processing, is a really important phase of the additive manufacturing cycle that includes all the operations that follow the simple printing procedure.

Regardless of the additive technology used, it’s always possible to differentiate between a post-production of the first type (Primary) and a post-production of the second type (Secondary). The first includes all the operations that are necessary regardless of the final use of the part: these are the cleaning and support-removal operations. The second, on the other hand, includes all operations aimed at the aesthetic or functional improvement of the part. Some examples are sandblasting, filling, priming, painting, and chemical smoothing.

Once the printing phase is over and the following post-processing phase has begun, it’s clear how the additive manufacturing process loses its nature of “pushbutton” technology.

In fact, the process directed towards the creation of a finished, ready-to-use part is complex and intricate, complicating the additive manufacturing workflow.

The fact that a large part of the techniques used to post-process additively manufactured pieces is manual – let’s think of sanding, fillers or primers- makes the finishing phase consistently impact times and costs of production.

Manual and non-automated finishing not only is slow and complicated, especially when pieces have complex geometries, but it also requires a large amount of labor and working space.

What costs and times are we talking about?

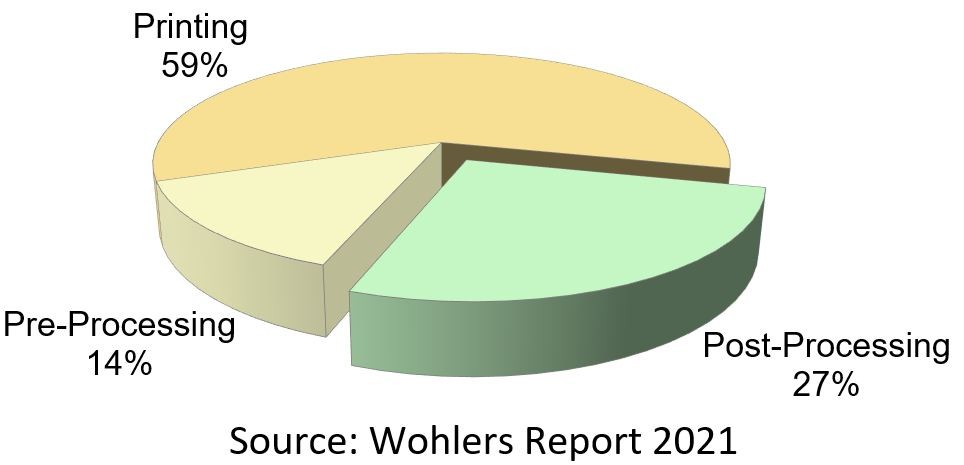

Many studies in recent years have shown the impact of post-production on production times and costs.

As far as production time is concerned, the results of a research conducted on several companies from different production sectors (such as automotive, medical etc..) and published in the online journal Techbriefs are worth mentioning. The research showed that post-processing, according to the users surveyed, would result in an increase in production time ranging from 17 percent to 100 percent of total production time.

On the other hand, as far as costs related to the post-processing phase are concerned, it is reported that, against a study of 124 service providers from 27 countries, the Wohlers Report 2021, a famous annual report on additive manufacturing by @Wohlers Associates, powered by ASTM International, estimated that 27 percent of additive manufacturing costs come from post-processing operations.

The annual study conducted by PostProcess Technologies comes to the same conclusions.

According to the U.S. company’s third annual report, 30 percent of survey respondents reported that post-processing activities require the use of about 26 percent of the annual budget, an increase of 7 percent in the percentages over the data reported the previous year.

What are the remedies to these costs?

Costs and time associated to post-processing procedures may seem inevitable and a certain obstacle to the greater diffusion of additive manufacturing.

However, the fact that costs and slowdowns are due to manual post-processing suggests that the solution to the problem may lie in the use of automated and innovative machinery.

There are now numerous companies that offer a range of automated solutions to reduce costs and post-processing time. In fact, only by reducing costs and post-production times, additive manufacturing can become more efficient and responsive and manifest its full potential.

To address this exact problem 3DFinisher was born. 3DNextech’s first automated post-processing device is specifically designed to address the needs of the additive manufacturing market, with the purpose of simplifying the production chain, expanding the fields of application of additive manufacturing and generating cost and time savings.