3D printing has been a major player in a wide variety of manufacturing sectors for years now, and it has been estimated that in 2021 alone, additive manufacturing products generated $6,229 billion in revenue worldwide, increase of 17.5 percent over 2020. [1]

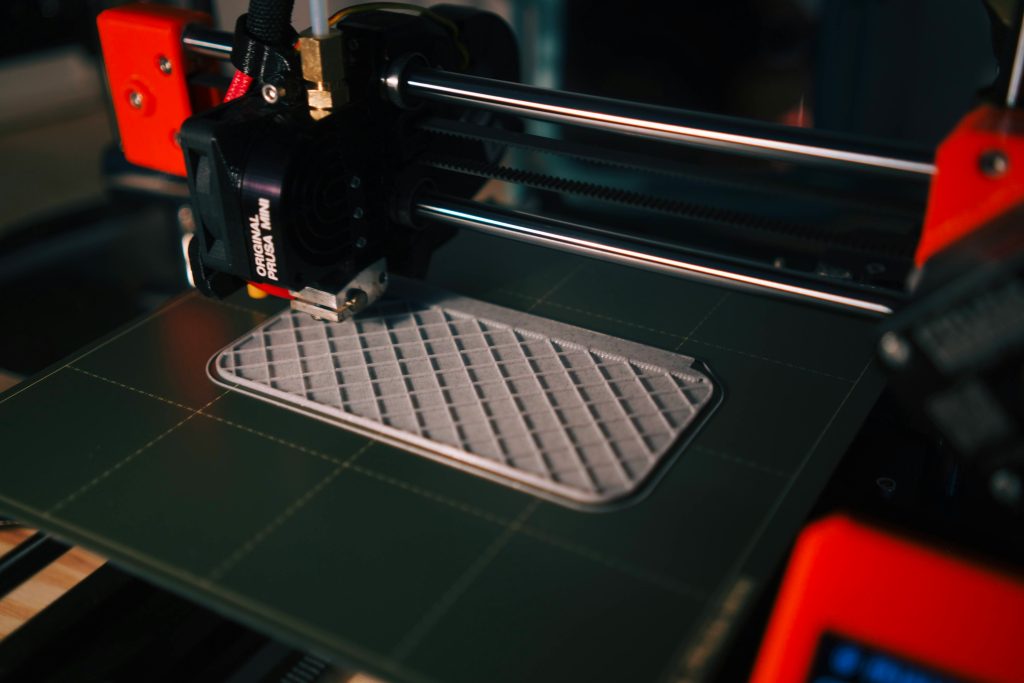

Among the various additive technologies, a significant portion of the market is dominated by FFF technology, or Fused Filament Fabrication. This technology involves the fabrication of polymeric material components by layering layers of material extruded from a nozzle.

While there’s no doubt about the simplicity with which a ready-to-use artifact can be obtained in a short time from a .stl file, one should not underestimate the inherent pitfalls of using FDM 3D printers. Like any machinery, technical skills are required in their use.

But what defects are most likely to be found on the surface of our 3D printed parts? And how can we fix them?

We’ve already discussed about the importance of quality prints (to read the article click here) and mentioned some issues that’s important to prevent. Today we take a closer look at one of them, stringing, and after identifying its most common causes, we will provide some tips on how to prevent it.

Insert CTA button: vd. Old website

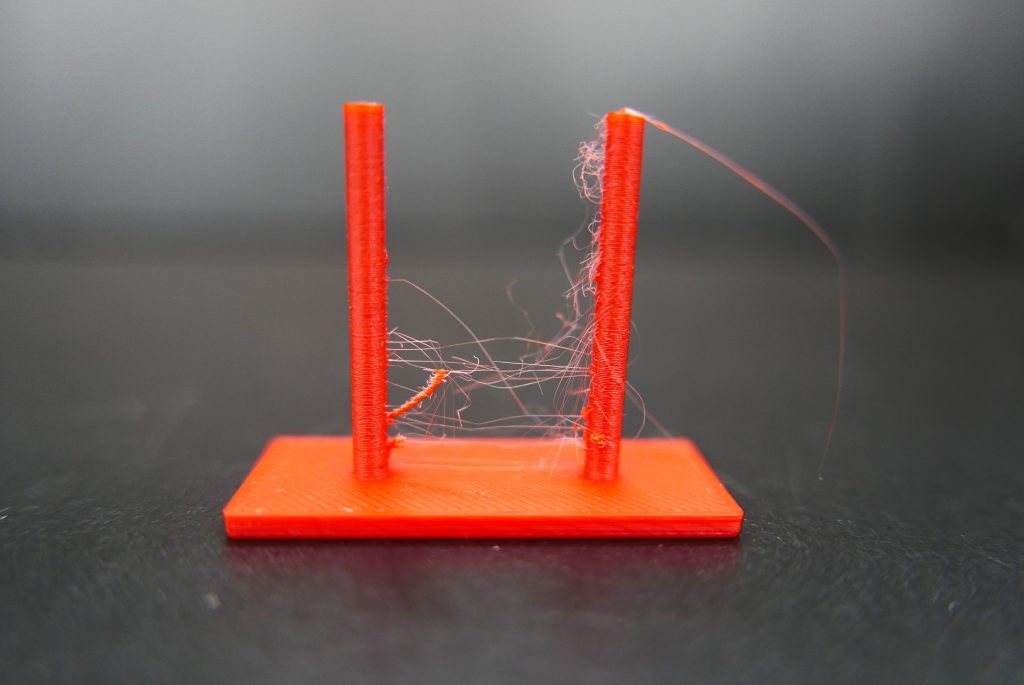

Stringing

Stringing consists of a series of very thin strands of material that stretch between parts of the model that are some distance apart.

It’s a form of “overextrusion” that shows up when filament oozes out of the moving nozzle when it’s not supposed to.

This problem usually occurs when the filament is not sufficiently retracted inside the extruder or when the material is too liquid and drips from the nozzle.

To prevent these imperfections, we need to pay attention to the settings for retraction, temperature and print speed.

How do these parameters affect stringing?

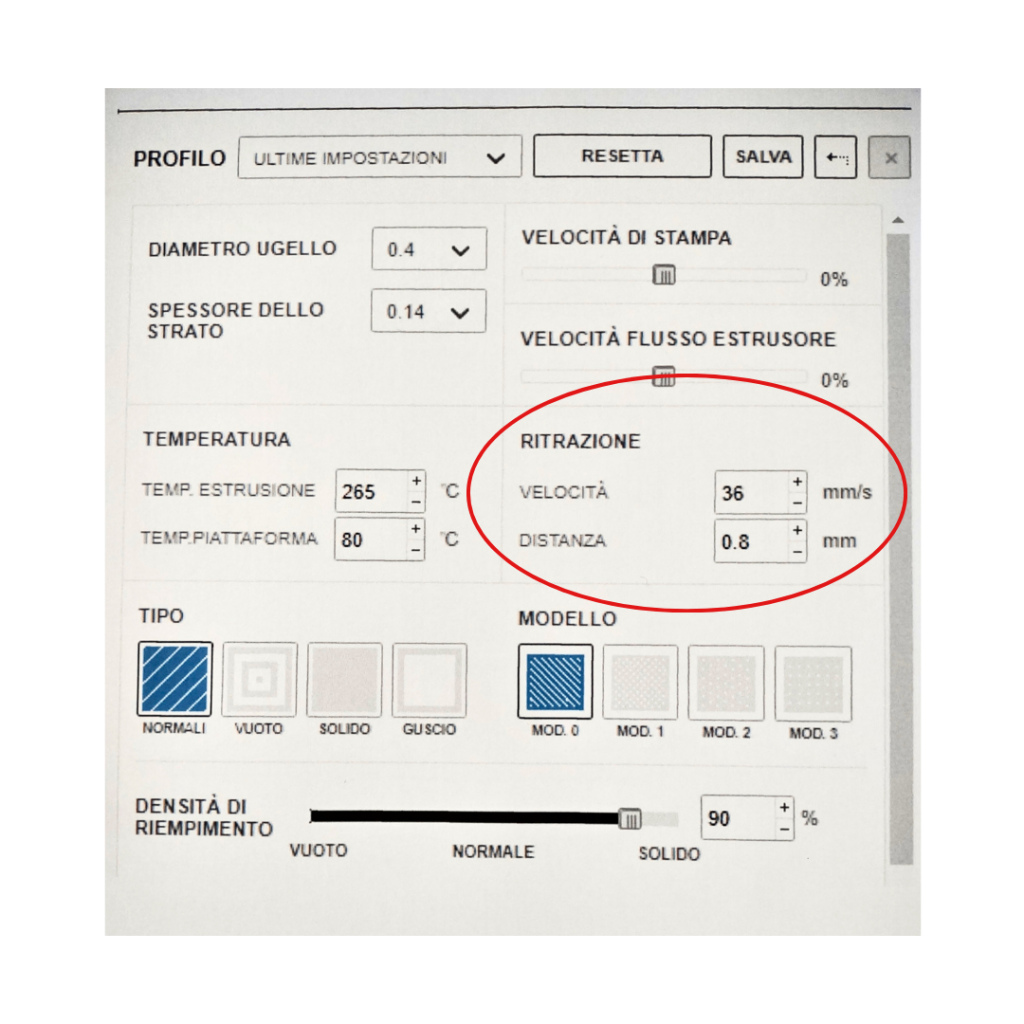

- Retraction: this function of the slicer pulls the filament into the extruder any time the device shouldn’t be printing. A reverse movement of the extruder motor prevents the material from exiting the nozzle. The retraction settings that affect stringing are the retraction length, speed, and minimum distance.

The retraction distance indicates how long the material retracted is. The optimum distance varies depending on the type of material we are dealing with and depending on the type of extruder (Bowen or direct).

Retraction speed is the speed at which the extruder retracts the filament into it. Basically, the extruder motor will turn in the reverse direction at a preset speed on the slicer, which is expressed in mm/s.

Finally, the minimum distance is the parameter which limits the number of consecutive retractions that the printer will perform in a given print area.

Retraction is critical to prevent stringing because if the filament is not retracted enough, or fast enough, the molten material can leak out and create the annoying fluff.

- As for the printing temperature, if too high for the chosen material, the filament will be more liquid than it should be and will leak from the nozzle during extruder movements.

- Slow printing speed is another possible cause of this defect. In fact, the melted plastic will have a longer time to flow out of the nozzle.

Solutions

If you want to avoid stringing, our advice is to check first check the retraction parameters set on your slicer and take note of the type of extruder your printer is equipped with. The type of material used will also affect the setting of the correct parameters.

It’s good to know that the recommended retraction distance for many direct extruders ranges from 0.5 to 2 mm, while for Bowens you can go up to 15 mm (Source: Simplify3d.com). [2]

Retraction speed, on the other hand, usually ranges from 25 to 45 mm/s.

Since stringing is caused by the material spilling during the printer pauses, as a first thing try increasing the retraction distance. Making different attempts may help you find the perfect combination of distance and speed.

In addition, check that the minimum distance setting is not too low, and if it is, try increasing it.

If adjusting the retraction does not prove effective, go to the extruder temperature and try lowering it by 5 to 10 degrees. This operation may prove decisive.

Finally, if even this does not solve your problem, increase the printing speed. Doing so will reduce the time during which stringing can occur.

Finding the right combination of parameters may take time, but that’s the only way to achieve flawless prints again!

If you have implemented all our tips but you’re still not satisfied with the way your prints look, and you’re looking smoother, shinier and even waterproof components, try our post-processing solution!

[1] Data extrapolated from Wohler’s Report 2022.

[2] For more precise parameters please consult your slicer settings.